Orifice Meters

ORIFICE METERS FOR CONTINUOUS BOILER BLOWDOWN FLOW CONTROL

(2 Models for Boilers up to 650 PSI)

- Two models, OM250 & OM650 with 4 orifice plate sizes to choose from

- Madden meters offer as little as 75 PPH to as much as 23,600 PPH of continuous boiler blowdown flow control

- Durable design intended for years of service life

- Important interior components have Stellite finishes and hardened to 500 Brinnel for added wear resistance

- Very little maintenance required

- Easy to keep clean with the 100 mesh screen and drain valve system

- OVERVIEW

- PRODUCT LINE

- ASSEMBLY BREAKDOWN

- RESOURCES

The Madden Orifice Meter gives the boiler operator precise repeatable control of the continuous blowdown flow rate. This boiler blowdown valve utilizes 17 different hole sizes which are drilled in the stainless steel orifice plate. Each hole is precision drilled to a diameter that will produce the flow shown on the flow chart, see pages 3 and 4. By selecting a larger hole the continuous blowdown flow is increased, or by selecting a smaller hole number on the index band the blowdown is reduced. Four different orifice plates (1A, 2A, 3A, and 4A) are available to provide a blowdown flow range suitable for the boiler operator to maintain the target boiler water quality level.

The boiler must have a continuous blowdown skimmer pipe installed inside the boiler drum, with the opening for the pipe within 6″ of the normal water level in the boiler drum. The Madden Orifice Meter may be mounted near the boiler or near a continuous blowdown heat recovery system. The constant blowdown flow provided by this Madden boiler blowdown valve makes it an ideal device for use in conjunction with a blowdown heat recovery system, see Madden Blowdown heat recovery system for details.

The Madden Orifice Meter has been in production for almost 50 years. The units are generally used on industrial boilers from 200 HP up to over 100,000 PPH steam production, operating at pressures from 50 psi up to 650 psi. One unit is required for each boiler. The meter can be utilized as the sole flow control device or pipe in parallel with a conductivity sensing blowdown control. The units are also used with non-fired boilers and reboilers used in refineries. The Madden Orifice Meter is guaranteed for up to 10 years against damage from cutting, wire drawing, or other distortion in the orifice plate.

| Part Number | Maximum PSI | Description | Weight lbs. |

|---|---|---|---|

| OM2501A | 250 | Orifice meter with orifice plate 1A installed | 64 |

| OM2502A | 250 | Orifice meter with orifice plate 2A installed | 64 |

| OM2503A | 250 | Orifice meter with orifice plate 3A installed | 64 |

| OM2504A | 250 | Orifice meter with orifice plate 4A installed | 64 |

| OM6501A | 650 | Orifice meter with orifice plate 1A installed | 80 |

| OM6502A | 650 | Orifice meter with orifice plate 2A installed | 80 |

| OM6503A | 650 | Orifice meter with orifice plate 3A installed | 80 |

| OM6504A | 650 | Orifice meter with orifice plate 4A installed | 80 |

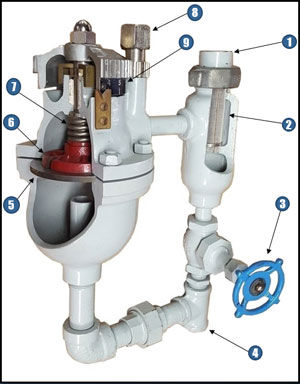

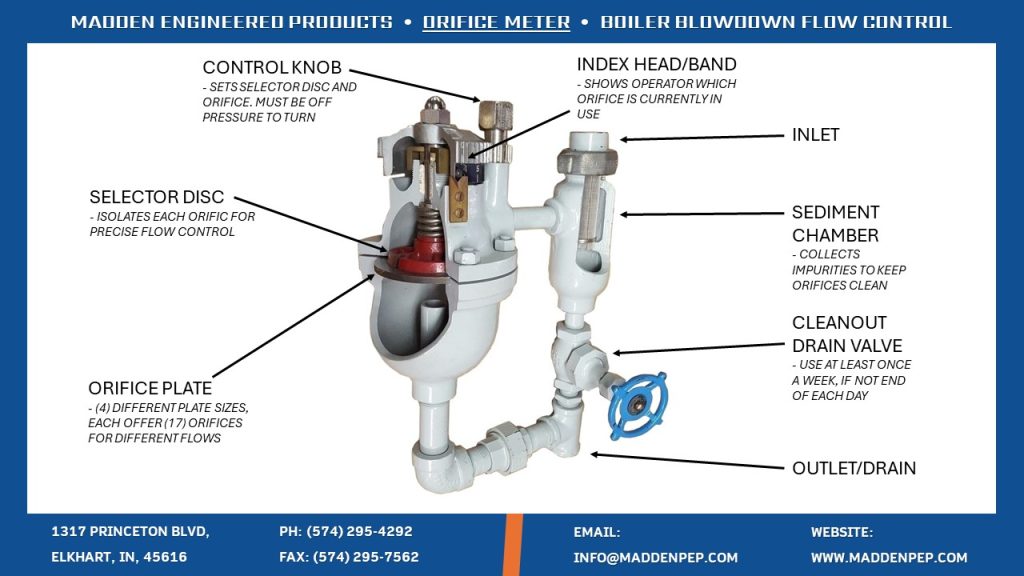

- Inlet – 3/4″ NPTF where the boiler blowdown line will connect

- Filter Screen Cylinder – Used to keep sediment from the dirty blowdown out of the Orifice Meter. Prevents clogging of the plate holes.

- Release Valves – Used for maintenance of the Orifice Meter. Allows for filtered sediment to be flushed out.

- Drain – Where the controlled blowdown will exit the meter and head to the Madden Recovery Unit. Also where the filtered sediment can be flushed out.

- Orifice Plate – Madden has two models of Orifice Meters, the OM250 which is rated up to 250 psi and the OM650 rated up to 650 psi. There are four plate sizes for each model having 17 different hole diameters to service a wide range of desire flow in pounds per hour.

- Rotating Selector Disc – Allows for the precise delivery of blowdown water through the appropriately sized hole in the orifice plate.

- Spring for Selector Disc – Holds rotating selector disc into place and allows for easier rotation of the selector disc.

- Adjustment Pinion Assembly – Wrenching this moves the rotating index head and orifice index band to the desired number which represents the size of the orifice hole the boiler blowdown will travel through.

- Orifice Index Band – Label with 17 numbers corresponding to a hole size in the orifice plate.