Using Madden Heat Exchangers for Pump Seal Flush Cooling

August 19, 2016 by Aaron Rhoade

Why Cool the Pump’s Seal Flush?

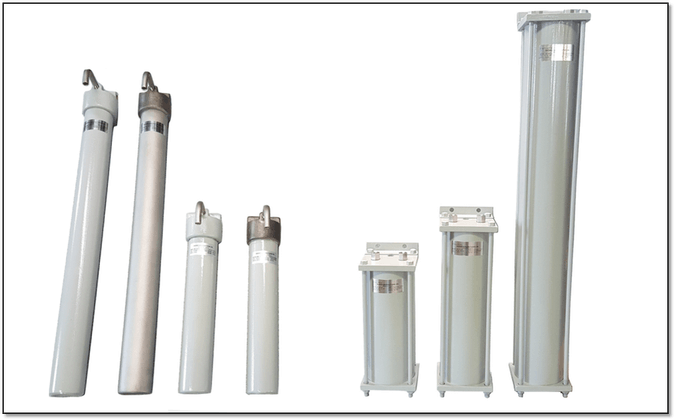

Heat Exchanger

Heat Exchanger

Certain types of centrifugal pumps and rotary pumps need their mechanical seals flushed out to achieve high reliability and effective sealing performance. The API has established piping plans for these seals. API Plan 21, Plan 22, Plan 23, and Plan 41 all require a heat exchanger to cool the seal flush liquid before being injected into the seal. This is where Madden Manufacturing comes in. We manufacture some of the most cost effective and durable liquid to liquid heat exchangers (sometimes directly called Pump Seal Flush Coolers) that the market has to offer.

When a centrifugal pump is pumping hot liquids there is potential for dilution and vaporization of the liquid. Cooling will improve lubricity and reduce the possibilities of dilution and vaporization, thus creating a more efficient and durable seal.

So if you have a system that needs to utilize API’s piping plan 21, plan 22, or the most common Plan 23 and Plan 41, consider a Madden Manufacturing Heat Exchanger for cooling your pump’s liquid seal.

Why use a Madden Heat Exchanger for pump seal flush cooling?

Madden Manufacturing heat exchangers are proving to be some of the lowest costing on the market as well as most durable. Madden heat exchangers can be completely disassembled for maintenance making the product line able to last for years. In the rare cases where the tubing/coil becomes clogged this also allows you to remove and replace the coil instead of replacing the entire unit, which is what most competitive products require due to their welded design.

Madden Manufacturing heat exchangers for pump seal flush cooling come in a variety of sizes and coil materials to be able to get nearly any flushed seal back under 140°F and in many applications, significantly lower than that. We offer copper tubing, for better heat transfer, and 316 stainless steel tubing for durability. The heat exchanging surface areas available are 1.3 sf, 2.6 sf, 1.9 sf, and 3.8 sf provided by 1/4” and 3/8” OD tubing.

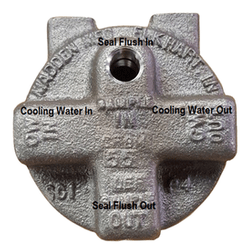

liquid to liquid heat exchanger

Why does Madden have more options than most of our competitors making heat exchangers for pump seal flush cooling?

Well, because we didn’t originally intend for our design to be used in this market. Madden manufacturing originally made heat exchangers, often called sample coolers, for testing and cooling boiler water and steam. After a while our distributors started reporting back that they were using our sample coolers as heat exchangers to cool centrifugal and rotary pump’s liquid seals with a lot of success. Our design and price point were attractive enough that many decided to give it a try, and sure enough, it worked and now Madden liquid to liquid heat exchangers are a competitive product in the pump seal flush cooling market.

And with all the options we have, Madden has your application covered.

Conclusion

If you are a distributor or an end user with a centrifugal pump and/or rotary pump that needs to cool the pump’s liquid seal, give us a call or an email to find a Madden pump seal flush cooler to consider against the competition. We can put together a calculation sheet for you to see exactly what temperature the seal flush liquid will come back out of our heat exchangers at, so you can be satisfied that a Madden sample cooler, heat exchanger, pump seal flush cooler, or whatever you want to call it, will serve your application well for years to come.

So give us a call at (800) 369-6233 or email in at info@maddenep.com and we’ll get your pump seal flush under 140°F for you. Thanks for reading and have a good one!