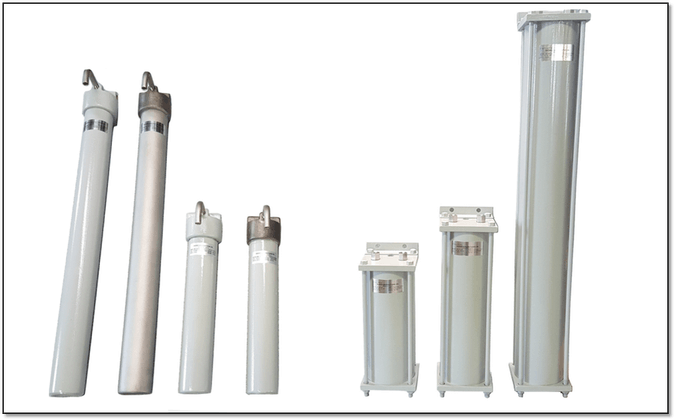

Miniature Heat Exchangers

- Designed to reduce high-temperature liquid samples to safe, usable temperatures for analysis

- 316 Stainless Steel and Copper tubing available

- Can be disassembled with standard tools for cleaning, or replacement of damaged coils

- Shell side pressure rating of 150 psi

- Two Models: Type 1 & Type 2

- FUNCTION

- PRODUCT LINE

Madden liquid to liquid heat exchangers is designed to reduce high-temperature liquid samples to safe, usable temperatures for analysis. They also function as an effective industrial coolers for pump seal flush liquid. The counter flow design efficiently cools the tube side liquid.

Miniature heat exchangers are available in copper and Type 316 stainless steel tube material. All Madden liquid to liquid heat exchangers can be disassembled with standard tools for cleaning, or replacement of damaged coils. Carbon steel shell parts are painted with gray acrylic enamel. The Shell side pressure rating is 150 psi. Madden Type 2 models may be constructed using a variety of materials to meet a customer’s specific requirements. Contact the factory for a quotation for applications with special material specifications.

Type 1

Type 1 miniature heat exchanger models have all the piping connections for the sample and the cooling water on the threaded cap on the top of the sample cooler. All coils are 1/4″ OD tubing, and all piping connections are 1/4″ NPT. Cooling water enters on the left and exits opposite on the right. The sample inlet connection is vertical on the top, and the cooled sample exits from the spout.

Type 2

Type 2 miniature heat exchangers offer both 1/4″ and 3/8″ OD tubing coils. Sample connections are 1/4 NPTF and are made on the top plate. Cooling water connections are 3/8″ NPTF located on both top and bottom plates.

Typically, liquid grab samples can be cooled with a 1.3 square foot coil surface area models for continuous cooling of samples for instrument probes, or for steam.

Miniature Heat Exchanger Types

Note: Coil side pressure ratings are based on maximum temperature of 400 deg F for copper coils and 1,000 deg F for stainless steel coils.

| Part No. | Max Coil PSI | Description – type, coil surface area, coil material, coil tube size | Weight |

|---|---|---|---|

| SC0001 | 300 | Type1, 1.3 sf, copper coil w/ CI head, 1/4″ OD tube | 15 lbs. |

| SC0002 | 300 | Type1, 2.6 sf, copper coil w/ CI head, 1/4″ OD tube | 25 lbs. |

| SC0003 | 3,000 | Type1, 1.3 sf, 316 SS coil w/ SS head, 1/4″ OD tube | 15 lbs. |

| SC0003A | 3,000 | Type1, 1.3 sf, 316 SS coil w/ SS head and SS body, 1/4″ OD tube | 15 lbs. |

| SC0004 | 3,000 | Type1, 2.6 sf, 316 SS coil w/ SS head, 1/4″ OD tube | 25 lbs. |

| SC0004A | 3,000 | Type1, 2.6 sf, 316 SS coil w/ SS head and SS body, 1/4″ OD tube | 25 lbs. |

| SC101 | 300 | Type2, 1.3 sf, copper coil, 1/4″ OD tube | 25 lbs. |

| SC102 | 3,850 | Type2, 1.3 sf, 316 SS coil, 1/4″ OD tube | 25 lbs. |

| SC103 | 250 | Type2, 1.9 sf, copper coil, 3/8 ” OD tube | 30 bls. |

| SC105 | 2,500 | Type2, 1.9 sf, 316 SS coil, 3/8″ OD tube | 30 lbs. |

| SC106 | 2,500 | Type2, 3.8 sf, 316 SS coil, 3/8″ OD tube | 50 lbs. |

| SC107 | 4,925 | Type2, 3.8 sf, 316 SS coil, 3/8″ OD tube | 50 lbs. |

| SC108 | 4,925 | Type2, 1.9 sf 316 SS coil area, 3/8″ OD tube | 30 lbs. |

| For Type 2 modes, 1/2″ to 1″ cooling water connections are available upon request. | |||

Note: Type 1 shell side pressure ratings are 300 PSI. Type 2 shell side pressure ratings are 150 PSI.