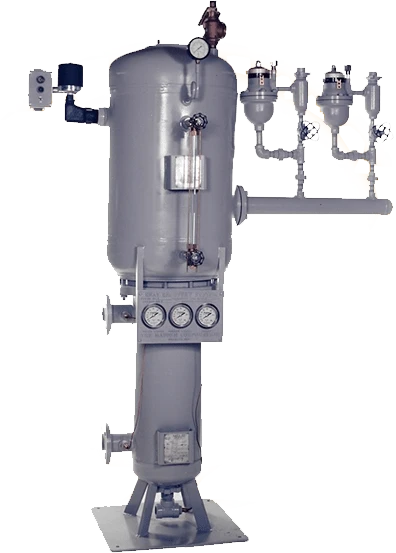

How to recover and reuse heat from boiler blowdown water: Part 1, focusing on Madden’s upper vessel of a HV model heat recovery system, the flash tank

November 15, 2017 by Aaron Rhoade

Madden Engineered Products designs and builds simple, rugged heat recovery systems for boiler and steam generator continuous blowdown. Our units safely and legally dispose of the boiler’s dirty surface water blowdown, all while recovering the heat and saving you money.

We offer two different styles, the vertical HV system and the horizontal HC system. Our boiler blowdown heat recovery products offer great performance and efficient economical return on your investment. Most units will pay for themselves in less than a year.

Madden HV and HC boiler blowdown heat recovery systems work automatically. When considering what all you need in your boiler room, these units are not something that will require much, if any, of the boiler operator’s attention. After our boiler water heat recovery systems are installed, they will function using the natural pressure generated by the boiler. The boiler will push the dirty surface water through its continuous blowdown pipe line to our system and from there, steam and water will go to their next locations without the aid of any pumps or other electrical equipment.

We recommend you inspect your unit for maintenance needs at least once or twice a year during a production shut down. It is certainly a good idea to give your gauges, sight glass, and float valve a glance more routinely, but for the most part, in comparison to some of the other components in the boiler room, you can leave our units in the back of your mind and trust your Madden heat recovery system.

As mentioned briefly in the introduction of this article, to recover the most heat possible from continuous boiler surface water blowdown, you need a flash tank for steam, and a heat exchanger for the remaining hot condensate. While most of our competitors offer two separate items for this process, Madden offers a complete system. This means only one piece of equipment to install, which saves you time, cost, and the head ache of designing your boiler room with yet another piece of equipment.

In this article we are going to focus on the upper vessel in our most popular system, the vertical HV models. We’ll go over exactly what it does, and how it saves money.

Recovering heat from the flash steam using a Flash tank.

So, how does recovering heat via the steam generated from a boiler’s continuous surface water blowdown work? It’s all about flash steam.

When controlling your boiler drum water quality and operating efficiency by removing suspended and dissolved solids through blowdown, you do so using the high pressure generated by the boiler. Hot, high pressure water will flash steam when entering a low pressure vessel, like the upper vessel of our HV units. Usually, the upper vessel on a Madden HV boiler blowdown heat recovery system, will be operating at the same pressure as a Deaerator (DA) Tank, as this is where we recommended sending the steam to be reused.

This means it is normally operating at 5-10 PSI. The most common applications that we quote our HV units for, are boilers operating anywhere from 100-250 PSI. This is a significant pressure drop and promotes a lot of the hot blowdown water to immediately flash and evaporate when entering our heat recovery system’s upper vessel.

10-20% of the volume of water that is entering the unit will immediately turn to steam. Of all the BTU’s it is possible to recover from boiler blowdown water, up to 50% of them can come from this 10-20% flash steam. Don’t just send this valuable energy to atmosphere!

So how does the steam save me money? What does it do in the DA tank?

Deaerator tanks are used for two main reasons, one, to remove oxygen from the boiler feed water, and two, to help preheat the water before being used in the boiler.

Steam accomplishes both.

Steam generated from your Madden HV heat recovery system will be piped into the DA tank and forced in at the bottom of the water level. This helps push oxygen up and out of the system through the DA tank’s vent. The steam will also heat up the water that will then be used as boiler feed water.

This heat that is now being added back into the system through the DA tank and boiler feed water system, would have otherwise been drained and vented into the atmosphere, only to dissipate and not be used again.

Boilers need to raise water temperature to above 212 degrees to create steam for your process, which requires burning some kind of fuel, most commonly natural gas. Every degree of heat (BTU) you can put into your boiler feed water, that doesn’t require burning fuel, equals money saved on fuel costs. By the end of the year, this can add up to thousands and thousands of dollars.

If you have the funds available, as cliché as the phrase is, it really is a no brainer to add a heat recovery system to your boiler’s continuous blowdown water line. Simple to install, easy to maintain, and pays for itself in a year or less.

Accessory components on the upper vessel of our heat recovery systems.

Sight Glass: we utilize a 22” long high pressure rated glass tube and valve set so you can monitor the water level in the upper vessel of your Madden HV model heat recovery system.

Pressure gauge: at the upper, center portion of the vessel, we install a pig tail and pressure gauge for easy monitoring of your flash tank and DA tank operating pressure.

Pressure relief valve: as an added safety feature to our automatic operating systems, we include a pressure relief valve that is sized to handle the maximum amount of steam that can be generated in your system.

High level alarm: our units use a simple float switch in the flash vessel to sound a high level alarm, for added security should something go wrong with the drain.

Inlet Manifold: often times it is paired with our Orifice meters for blowdown flow control, the inlet manifold is pre-fabricated 3” pipe with up to (6) 1” NPT connections installed on it. It’s essentially a ready-made header to route all of your boilers through.

Hand hole: for easy inspection and access to the float valve, a 6” X 8” hand hole is installed on the back of the flash tank.

ASME Name plate: also located on the back, we include the HV unit’s ASME VIII, Div. 1 with National Board Serial number and “U” stamp via an all-inclusive name plate.

Conclusion

If you have an existing boiler room, or are planning to build a boiler room with a boiler (or boilers) that produce enough steam to require continuous surface blowdown, look into getting a heat recovery system. Ridding your boiler of dirty water significantly helps your boiler operate efficiently, turning into fuel cost savings. But don’t settle for less than the best.

For your consideration, the mid line Madden HV units cost around $15,000-$18,000. When you take the standard amount of blowdown that these units are sized for (about 5,500 PPH for this example), and the current cost per therm to heat your boiler (about $0.35 currently) a Madden HV070 would be saving you $45,000 a year in fuel costs.

Again, a no brainer.

We hope you found this article informative and again, if you have a need or interest in heat recovery please give us a look. You can contact us direct or find one of our reps/distributors near you.

In Part 2 of this article we’ll go over the lower vessel in our heat recovery systems, the heat exchanger.

Thanks for reading our article, and have a good one!

(PH: 800-369-6233, Email: info@maddenep.com)