How a Madden Orifice Meter can help save money on a boiler’s continuous blowdown application

January 6, 2017 by Aaron Rhoade

There are many pretreatment options for boiler feed water to help ensure clean and efficient boiling in your application. However, even with the best pretreatment, impurities in your boiler water can still occur via suspended and dissolved solids forming. Suspended and dissolved solids can carry out of the boiler with the steam causing damage to piping and even other in-line process equipment. And if that isn’t enough, suspended solids can form sludge inside of your boiler greatly affecting boiler efficiency and heat transfer.

Bottom line, if you aren’t continuously, or at least regularly, blowing down boiler water, you are losing money. The Madden Orifice Meter can help with significant cost savings in your boiler blowdown application by consistently and accurately allowing a small percentage of boiler water to blowdown continuously, allowing clean pretreated feed water to take its place.

Why is proper boiler blowdown important?

According to the North Carolina Division of Pollution Prevention and Environmental Assistance, the benefits of boiler blowdown are as follows:

- Less water needed, therefore less fuel and treatment chemicals needed

- Significant decrease in maintenance and repair costs

- Less manual supervision for other tasks are required (with automatic control, like with the Madden Orifice Meter)

- Because of the reduction in consumption, disposal, treatment and heating of water, there is a significant reduction in operating costs

- Minimized energy loss from boiler blowdown can save about 2 percent of a facility’s total energy use. And if we might add, if energy savings is of high importance to you, take a look at our Madden Heat Recovery systems to see if there is a unit right for your application. (make this a link)

You can find the complete NCDENR article here.

Simply put, you want to strive for 100% of the heat from your boiler to transfer to the water and steam. Dirty water in your boiler means more fuel needed to be burned to produce the same amount of steam and heat.

A Madden Orifice Meter is one component in the process of reaching optimal boiler efficiency.

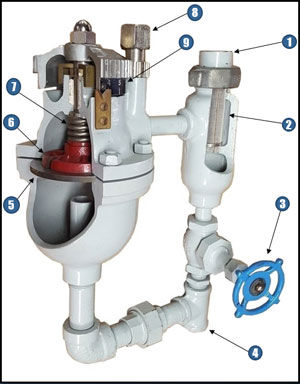

How the Madden Orifice Meter (Boiler Blowdown Valve) Works

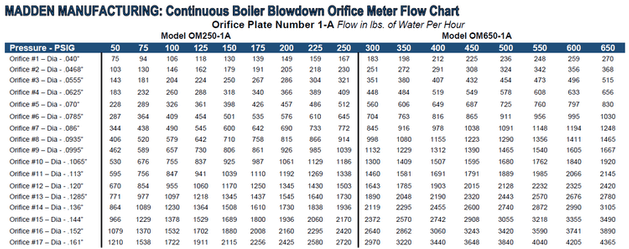

Madden Manufacturing produces two types of orifice meters, one designed for 250 PSI applications and another to handle up to 650 PSI applications. Each of these designs have 4 different orifice plate sizes available to choose from. These orifice plates have 17 different orifice hole sizes in them, each bigger than the one before.

The Madden Orifice Meter design is intended to set it and forget it. These rugged, heavy duty boiler blowdown valves use the boiler’s operating pressure to control and produce a consistent blowdown amount. Based on the boiler’s operating pressure and orifice hole selected, you will know your blowdown amount and can be confident it will remain consistent 24/7/365. Very little maintenance and monitoring required.

To better understand what you will get from a Madden Orifice Meter, and how to select the plate size for your application, take a look at this chart below:

So, for example, if you have a boiler operating at 125 PSI, and want to blowdown 1,000 PPH of dirty boiler water, you would need plate size 1A to be installed in your OM250 Madden Orifice Meter and set the unit to orifice # 12. (For a complete look at all orifice plate sizes and capacities, see our OM_data sheet_2016)

If you ever need to change the amount of blowdown going through your Madden boiler blowdown valve, remember to do so off pressure. Pressure is what helps ensure a tight seal between the orifice plate and selector disk and makes it nearly impossible to adjust this blowdown valve while in operation.

To read more about our Orifice Meters, please see our product page Orifice Meter: blowdown flow control!

Conclusion

If you think your boiler operation could be more efficient, or if you are nervous you may be wasting fuel and therefore money, give Madden Manufacturing a call (PH: 800-369-6233 or email: info@maddenep.com). Stu or Aaron will be more than happy to walk you through sizing a boiler blowdown valve or even one of our heat recovery systems. It can’t hurt to at least check!

And don’t forget about seeing if one of our certified reps or distributors are in your backyard. These experts can provide even more knowledge being near you when it comes to questions about your next Orifice Meter.