Have your boiler blowdown waste water pay for boiler fuel costs: Boiler blowdown heat recovery systems by Madden

January 15, 2019 by Aaron Rhoade

Boiler rooms that total to 250 BHP or higher (or think steam production around 10,000 PPH or higher) often utilize continuous surface blow down on top of the standard intermittent bottom blowdown process. Continuously blowing down surface water helps keep the boiler free from scale build up on the water or fire tubes and keeps suspended solids and other impurities from hindering efficient boiler operation.

This waste water being sent to drain can help pay for your boilers fuel cost via BTU recovery through flash steam and/or a heat exchanger. Dirty boiler blowdown water still contains valuable heat. Whether your boiler uses natural gas, coal, electric, wood, etc. as the fuel being burned to boil water, fuel costs add up by the end of the year. This surface blowdown process contains “free” heat that would otherwise be wasted (and thus require more fuel consumption with the burner) if a heat recovery system is not implemented. Madden heat recovery systems efficiently recover BTU’s from this process and put them back into the makeup water side of the boiler without contaminating the process with the impurities contained in the waste blowdown.

“Heat” is measured in British Thermal Units. BTU’s are defined as the amount of heat needed to raise one pound of water by one degree Fahrenheit. Burning gas, wood, coal, or using electricity is one way to provide your boiler water with the necessary amount of BTU’s, which costs money. If you have a heat recovery system on your boiler blowdown water, it can cut your boiler’s BTU needs significantly.

Let’s take a look at how the Madden Heat Recovery System product line recovers heat from boiler surface water blowdown.

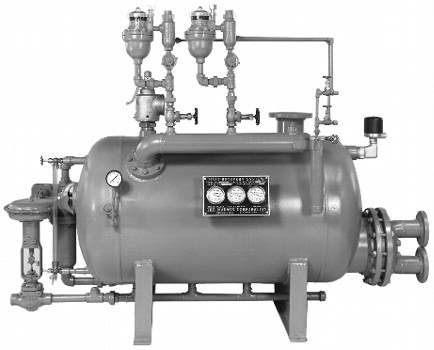

Madden’s HV and HC model heat recovery systems

Madden makes a vertical heat recovery system designed to save floor space, as well as a horizontal heat recovery system designed to offer larger capacities. Both systems work using the same two principals of recovering heat. These principals are recovering heat via flash steam and recovering heat via heat transfer through a shell and tube or U-tube bundle type heat exchanger.

How it works: the hot, high pressure boiler blowdown water continuously draining from your boiler will flash off steam when it enters a lower pressure vessel (ie. our HV or HC heat recovery systems). This flash steam makes up the majority of the BTU’s available to be recovered in boiler blowdown water. We recommend that the vent on our flash vessel be piped back to the deaerator tank to be reused in the system.

The remaining hot water that did not flash when entering the low pressure vessel, is then passed through a heat exchanger for the final BTU recovery. Cold make up boiler feed water is piped through the Madden HV or HC heat recovery system via the heat exchanger/U-tube bundle portion of the unit. This water cools the remaining hot boiler water to a safe, legal temperature to be sent to the sewer, and while doing so, the heat exchange allows for the makeup water to heat up, entering the boiler system at a warmer temperature than it would otherwise. This means less gas, coal, wood, or electric needing to be used to boil the water.

Expected savings using heat recovery systems on boiler waste water

If you are considering heat recovery for your boiler room application(s), Madden can offer an expected performance and savings calculation based on your boiler(s) specifications and the appropriate Madden heat recovery system model. We calculate the expected BTU’s in the flash steam and the expected available BTU’s that can transfer through the heat exchanger/U-tube bundle. All that is needed is boiler operating pressure, steam production and blowdown flow rate, and if known, the current cost per therm at your facility. With these inputs, Madden uses the expected flash steam and the heat exchanger capacity to find how many BTU’s will be recovered from the boiler drain water. Using this count and the cost per therm, Madden can offer a detailed and accurate report on the total expected savings by showing the temperature rises in makeup water and total flash steam recovered.

Madden heat recovery systems generally pay themselves off in 6 months, sometimes even sooner depending on the application. The boiler room can get complicated, there’s a lot of equipment involved in steam production, but two mainstays are the D/A tank removing oxygen from water via steam processes and make up water to feed the boiler; Madden heat recovery systems add to both processes without a recurring cost, keeping your fuel costs lower. Your company can also boast a conscious effort towards the green movement as not even your boiler’s waste water goes to waste.

If your boiler room doesn’t have a boiler blowdown heat recovery system, you’re draining money to the city sewer.

Conclusion

Boiler surface blowdown doesn’t have to be wasted water, it can be utilized one last time to help your boiling application. Blowing down dirty water from the boiler helps keep the process free of impurities that hinder boiling. A clean boiler boils efficiently, using as little fuel as possible, and adding a heat recovery system to this process significantly boosts this efficiency.

Focus on limiting your fuel consumption and reap the benefits of cost savings and reducing your carbon footprint.

Madden representatives are a great place to start with any inquiries you may have about boiler waste water heat recovery. We would greatly appreciate the opportunity to work with you to see what kind of fuel savings could be provided with a heat recovery system in your boiler room.

To learn more about our heat recovery systems please visit the product page here.