Controlling continuous boiler blowdown flow rate using heavy duty control valves: Madden’s Orifice Meter

April 5, 2018 by Aaron Rhoade

The two main ways to control surface blowdown in boilers are by conductivity sensors and manual valves. Conductivity sensors work by measuring the conductivity of the boiler water and then automatically blowing down dirty surface water for a set amount of time until it reaches the operator’s desired conductivity.

Manual valves work on a percentage principal. Boiler operators look at water quality and other operating conditions to come up with a percentage of surface water to continuously blowdown. This percentage is based on the boiler’s average steam production. The blowdown percent range needed can vary greatly depending on the boiler room conditions and the water available for boiling.

Due to the harsh conditions and broad blowdown ranges required, Madden Manufacturing’s Orifice Meters are a great product in comparisons to other manual boiler blowdown valves. Our boiler blowdown flow control units offer great durability and a broader range of blowdown flow control to meet the vast requirements of your boiler room(s) blowdown applications.

With the Madden Orifice Meter, the boiler operator can pick from 1 of 17 different orifice sizes (orifice sizes being directly related to a precise flow rate), set it, and forget it. These boiler blowdown flow control units last many years longer than competing boiler blowdown controls.

Let’s dive into what exactly our Orifice Meters are, and how they work.

Beefed Up Blowdown Valve, the Orifice Meter

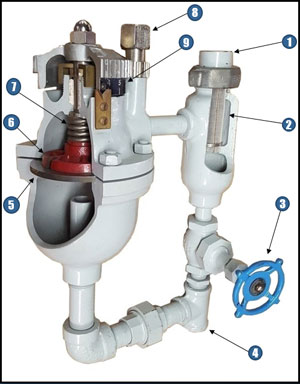

Madden Manufacturing Orifice Meters give the boiler operator precise repeatable control of the continuous blowdown flow rate. The orifice meter’s body and accompanying piping are made from heavy duty cast iron and steel parts to survive the harsh, heated conditions of the boiler room.

Inside the body of the Orifice Meters are the two main components that give the operator the precise control we’ve been speaking on, the orifice plate and the selector disc. Extensive care and extra treatment goes into these parts to make sure they will hold up to hot, dirty boiler blowdown water for years and years of service.

The orifice plate is made with 420 stainless steel material and heat treated to 500 brinnell hardness. This allows it to withstand extreme temperatures and discarded dirty boiler water for years on end. The orifice plates have 17 different sized orifices drilled into them to choose from, giving the operator a wide range of control for the blowdown flow rate. These orifice plates are lapped to a mirror finish with a tolerance of three light bands (.00003”); this is what allows for the selector disk and the orifice plate to mesh together for a 100% seal, no boiler water will leak in the unit, it is restricted to only passing through the selected orifice.

The selector disc has a Stellite surface hardening coating and is lapped to the same finish and flatness as its mating orifice plate to insure the leak free seal. The disc has an index slot which exposes the desired orifice. The selector disc rotates when the adjustment key is turned from one index number to another. The identification of the orifice number is show on the top of the unit using an index head band.

Madden has a total of 8 Orifice Meter Models; there are two different strengths of Orifice Meter bodies, and between those two bodies each has 4 different possible orifice plate sizes to choose from. Let’s see exactly how broad of a range Madden Orifice Meters can provide for your boiler room’s blowdown applications.

Madden Boiler Blowdown flow control goes from as little as 75 PPH all the way up to 23,590 PPH

Let’s start by explaining the two different sizes/strengths of blowdown Orifice Meters we offer, the OM250 and the OM650. These units use the exact same internal parts (orifice plate, selector disc, stem, etc.), but the bodies of the OM650’s are a little bigger, thicker, and made of cast steel to handle the higher temperatures and pressures. The OM250’s are made of cast iron.

The reason being, the OM250’s are designed for boilers that are operating up to 250 PSI. The OM650’s are designed for boilers that are operating up to 650 PSI.

For these 2 models, we have 4 different orifice plate sizes to choose from. Simply called size 1A, 2A, 3A, and 4A plates. The orifice plates each have 17 different orifices drilled into them, and each orifice is slightly bigger than the last. This carries through from the 1A sized plate all the way up to the 4A sized plate.

So how do I know which orifice plate size I need?

The first thing to consider is the percentage or volume of blowdown you want leaving your boiler to keep the boiler water clean.

Let’s use an example. You have a 500 HP boiler operating at 150 PSI, producing an average of around 17,250 PPH of steam. To keep the water free from dissolved solids and scale build up, you’d like to constantly, slowly drain the dirty water, at about 3-5% of steam production. So to be safe, let’s find an orifice plate size that would allow for a 1-10% blowdown range with this application.

The next thing you need to do is look at a Madden “Continuous Boiler Blowdown Orifice Meter Flow Chart” which can be found in our OM2016 data sheet, (if you have already purchased a Madden Orifice Meter it should come along with the unit, if not, see our literature section on our website).

From here, it’s pretty simple.

Sticking with the example above, the first thing to do, is look at the column under your operating pressure, ignore the other columns. At 150 PSI, the numbers below show you what each orifice in that orifice plate will restrict and maintain the boiler blowdown flow rate to. Plate size 1A, 2A, 3A, and 4A all have unique flow control ranges at 150 PSI boiler operating pressure.

So for this example, if we want a range of 1-10%, 172 PPH to 1,1725 PPH, we would want to select an OM250 Orifice Meter model, installed with a size 1A plate. With 150 PSI behind the boiler blowdown, a size 1A plate offers blowdown flow control as low as 130 PPH and as high as 2,115 PPH.

Conclusion

If you’re in the market for boiler water blowdown flow control, consider a Madden Orifice Meter. Our units provide the best combination of durability and flexibility in performance. You can set it and forget it, trusting the Orifice Meter to control your boiler’s blowdown with a tremendous service life.

If this is something of interest for your boiler room application, give one of our sales reps a call, or call us direct, we’d be happy to send you whatever you need to consider our product.

As always, thank you for reading our article, and have a great day!

Ph: 800-369-6233 | Email: info@maddenep.com