Condensate Coolers

CONDENSATE COOLERS FOR TEMPERING HOT DRAIN LINE PROCESSES

(2 Standardized Models, Build to Spec’ Available)

- COST EFFECTIVE – One of the least expensive ways to legally and safely discharge hot drain processes.

- FAST LEAD TIMES – Madden keeps standard materials stocked to build and ship in 1 week or less.

- PRE-DESIGNED – 2 standard models conveniently pre-sized to cover a wide range of applications. Custom models available upon request.

- CONSTRUCTION – Standard construction includes Non-ASME code carbon steel vessels rated to 150 PISG. Madden offers 316SS and/or ASME code stamped construction as an option.

- APPLICATIONS – Condensate coolers are intended for low pressure, hot drain applications. Such as steam trap discharge, steam to water heat exchanger discharge, or autoclave/sterilizer drain lines.

- Check out our most up to date DATA SHEET.

- CONTACT US for sizing assistance and pricing.

- OVERVIEW

- FEATURES AND APPLICATION NOTES

- RESOURCES

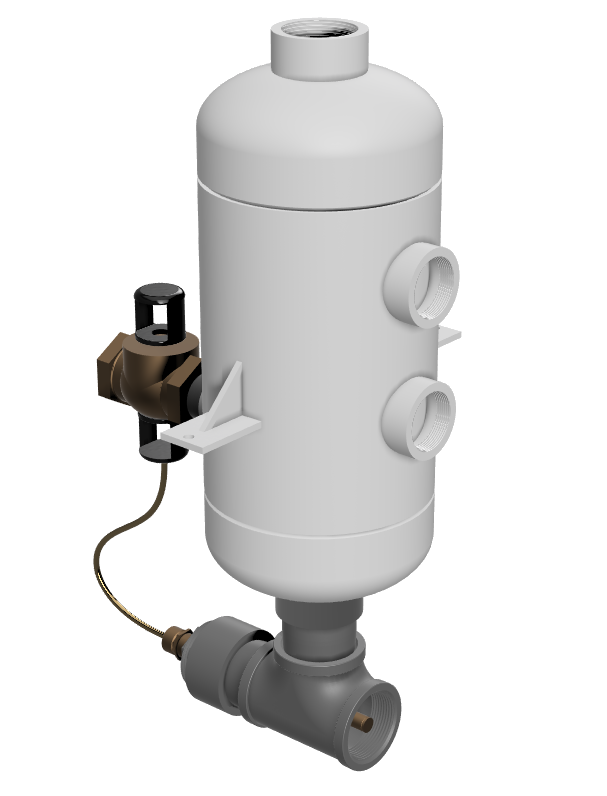

Madden Condensate Coolers are designed to quench hot condensate drain processes with a cold-water supply to bring the resulting mixture down to acceptable temperature limits. When hot condensate enters the vessel a self-operating cold-water valve actuates, allowing cold water to enter and quench to a field set standard temperature control range of 60-140 deg F.

Common applications are steam trap drain lines, steam-to-water heat exchanger drains, or autoclave/sterilizer drain lines.

FABRICATION NOTES:

- Welding Procedure – Madden WPS No. GMAW-PIPE-01 (request if needed for review)

- Process: Gas Metal Arc Welding

- Weld Type: Butt, Fillet, and Branch Connections

- Materials: ASTM A106 Grade B, ASTM A234 Grade WPB

- Root opening (Gap): 1/16”; Root Face: 1/16”; Groove Angle: 60 deg

- Gas Type: 75% Argon / 25% Carbon Dioxide

- Madden fabrication standard includes (3) welding passes. Root, Fill, and Cap.

- Madden follows ASME B31.1 standards.

- Hydro Test: Condensate coolers are rated to 150 PSI, tested for 30 minutes at 195 PSI

- Finish: red oxide primer with gray acrylic top coat on exterior only.

- ASME Option: For clients requiring Condensate Coolers to be ASME Code stamped:

- U-1A form and National Board Serial Number provided

- Built to ASME Div 1, Sec VIII, BPVC 50 PSI or 150 PSI

Fast Lead Times. Typically 1-2 weeks after receipt of order.

Robust. Sch 40 Carbon Steel (standard) and 316SS (option) vessel material.

Cost Effective. Non-ASME Code vessels, built following ASME B31.1 standards.

ASME stamped designs are available for a cost adder.

NOTE: Condensate receivers should not be used as a flash tank, they are intended for ≤ 15 PSIG drain processes. For higher pressure condensate drain applications, either pass the process through a general flash tank first or consider a Madden Blowdown Separator system as an alternative solution.

- End User Discretion: Condensate coolers (receivers) installed on 15+ PSIG drain lines without a dedicated flash tank must have their vent lines run unimpeded into a safe atmospheric area (ex. roof or to another ASME atmospheric flash vessel). Condensing equipment and/or any valves should NOT be installed on the vent line.

- Condensate Cooler Data Sheet

- (Coming Soon – Operator’s Manual)